===

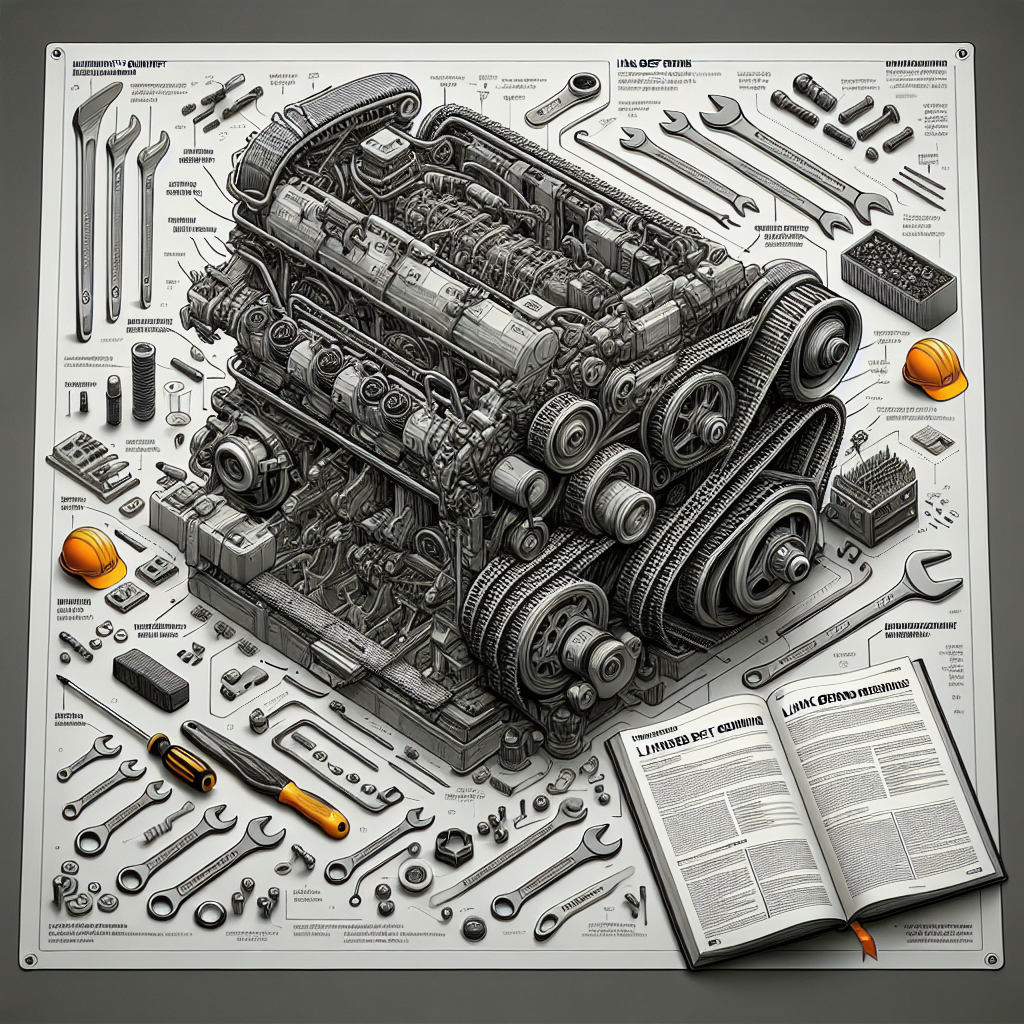

Repairing and overhauling Link Belt engines is a complex task that requires careful consideration and adherence to manufacturers’ guidance. These engines are known for their durability and high performance, but like any other machinery, they require regular maintenance and occasional repairs. In order to ensure the longevity and optimal functioning of Link Belt engines, it is crucial to follow the guidance provided by the manufacturers. This article will explore the importance of manufacturers’ guidance for Link Belt engine repairs, the process of overhauling these engines, key considerations for repairing them, and the benefits of following manufacturers’ guidance for engine maintenance.

The Importance of Manufacturers Guidance for Link Belt Engine Repairs

When it comes to repairing Link Belt engines, manufacturers’ guidance plays a vital role. These engines are designed and built by experts who have extensive knowledge and experience in their construction and operation. The manufacturers provide detailed instructions and specifications that are specifically tailored to these engines, ensuring that repairs are carried out correctly and efficiently.

By following manufacturers’ guidance, technicians and mechanics can have confidence in their repair work, knowing that they are using the correct tools, parts, and procedures. This not only ensures the safety of the engine but also helps to prevent further damage or issues that may arise from improper repairs.

Moreover, manufacturers’ guidance often includes valuable troubleshooting tips and common problems to look out for during repairs. This can save significant time and effort by helping technicians diagnose issues accurately and swiftly.

Understanding the Process of Overhauling Link Belt Engines

Overhauling a Link Belt engine involves a comprehensive inspection, repair, and replacement of various components. It is a thorough process that aims to restore the engine to its original condition and improve its performance. Manufacturers’ guidance provides step-by-step instructions on disassembling the engine, inspecting each part, identifying worn-out components, and replacing or repairing them as necessary.

During the overhaul, technicians also follow manufacturers’ guidance to ensure proper cleaning and lubrication of the engine. This helps to remove any contaminants and maintain the engine’s efficiency and longevity.

Key Considerations for Repairing Link Belt Engines

Repairing Link Belt engines requires careful consideration of several key factors. Manufacturers’ guidance provides detailed information on the specific tools, equipment, and parts required for each repair. It also outlines the recommended procedures to follow, including torque specifications, tolerances, and alignment procedures.

Technicians must also consider the safety precautions outlined in the manufacturers’ guidance. These precautions may include wearing protective gear, following proper lockout/tagout procedures, and handling hazardous materials safely.

Additionally, manufacturers’ guidance often includes information on troubleshooting common issues and providing solutions. This helps technicians identify the root cause of a problem and apply the most appropriate repair techniques.

Benefits of Following Manufacturers Guidance for Engine Maintenance

Following manufacturers’ guidance for engine maintenance offers numerous benefits. Firstly, it ensures that the engine operates at its optimal level, delivering peak performance and efficiency. Regular maintenance, as recommended by the manufacturers, helps prevent costly breakdowns and extends the engine’s lifespan.

Manufacturers’ guidance also helps to maintain the warranty of the engine. Deviating from the recommended maintenance procedures or using unauthorized parts can void the warranty, leaving owners liable for any repairs or replacements.

Furthermore, manufacturers’ guidance ensures that the engine remains compliant with industry standards and regulations. This is particularly important for industries that require adherence to specific safety and environmental regulations.

In conclusion, repairing and overhauling Link Belt engines requires manufacturers’ guidance to ensure the correct procedures, parts, and tools are used. Following this guidance ensures that repairs are carried out safely, efficiently, and in compliance with industry standards. By adhering to manufacturers’ guidance, technicians can optimize the performance and longevity of Link Belt engines, ultimately saving time, money, and preventing potential issues down the line.

===

For more comprehensive information on repairing and overhauling Link Belt engines, visit Link Belt Manual. Their extensive collection of manuals and guides offers invaluable resources for technicians and mechanics working on these engines.