Link-Belt Crane service and repair manual PDF

If you need to repair or service your Link-Belt Crane, you might be used to turning to printed manuals for guidance on procedures, tips, and troubleshooting. While service manuals from third-party publishers like Haynes or Chilton are available, they tend to be broad and may lack the in-depth detail that professional mechanics require. The official link-belt-manual.com website provides genuine Link-Belt Crane service manuals directly from the factory. These are the same OEM manuals used by certified technicians and authorized Link-Belt dealers. Often referred to as the TIS (Technical Information System) or FSM (Factory Service Manual), these manuals cover all major repair components in detail. They include illustrated diagrams, diagnostics, tests, adjustments, operating theory, and complete repair procedures. All manuals are available as downloadable, easy-to-navigate PDF files. Simply choose your crane model category from the menu to find the exact manual for your Link-Belt Crane.

Showing 1–9 of 1096 results

-

High Quality Manuals Link Belt Crane HHT-8690 Service Repair Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 100RT Crane Full Complete Repair Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 100RT Crane Full Complete Service Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 100RT XL Crane Full Complete Repair Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 100RTXP Crane Full Complete Repair Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 100RTXP Crane Full Complete Service Manual PDF Download

Sale! $89.00 Add to cart -

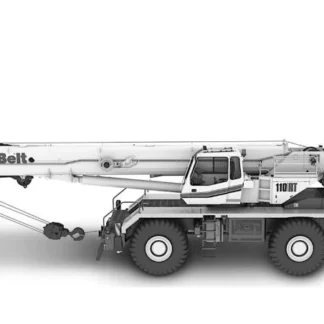

Link Belt 110RT Crane Full Complete Service Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 110RTXP Crane Full Complete Repair Manual PDF Download

Sale! $89.00 Add to cart -

Link Belt 110RTXP Crane Full Complete Service Manual PDF Download

Sale! $89.00 Add to cart

Showing 1–9 of 1096 results